Sustainability

Discover how our technologies contribute to a more sustainable food industry.

Our Sustainability Commitment

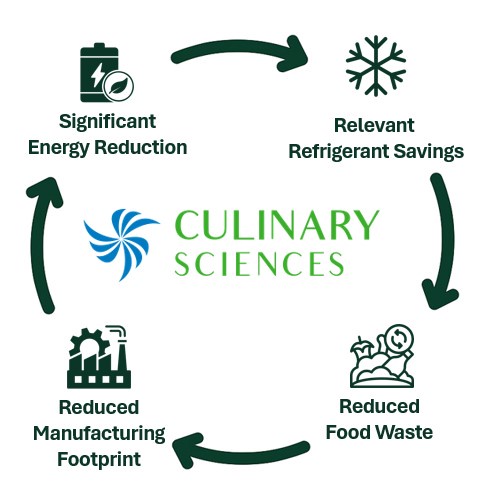

Sustainability is a core focus across the food industry as players prioritize reducing environmental impact and emissions throughout their value chain. At Culinary Sciences Inc., sustainability is a guiding principle. Our PrecisionVac technology was developed with this in mind, offering significant contributions to these industry-wide goals.

Our solutions directly address environmental stewardship through energy efficient operations and reducing food waste across the supply chain. This optimization translates directly into considerable CO2 emission savings for our customers. We are committed to helping our clients achieve their sustainability objectives, delivering measurable environmental benefits alongside clear business advantages.

Energy-Efficient Conditioning Systems

Our technologies dramatically reduce energy consumption compared to conventional methods.

Energy Efficiency

Our PrecisionVac technology uses just 20% of the energy required by conventional refrigeration systems for the same cooling capacity. This dramatic reduction translates to lower operational costs and a significant decrease in carbon emissions.

- The average energy consumption in a PV-Rack is approximately 30 kWh/MT.

- Traditional blast chillers typically consume 150 kWh/MT for the same cooling capacity.

- This represents an 80% reduction in energy usage.

Sustainable Refrigerants

CSI’s PrecisionVac system is designed to minimize the use of environmentally harmful refrigerants common in traditional cooling equipment. By avoiding these refrigerants in the PV-Rack and using minimal amounts of a more sustainable alternative in a closed system, we reduce the environmental footprint.

- The PV-Rack is R-404A free, avoiding a refrigerant known to be very dangerous to the environment.

- Our systems use a closed-loop refrigerant system that minimizes leakage.

- We’re continuously researching and implementing more sustainable refrigerant options.

Reduced Food Waste

Our technologies help combat food waste through improved preservation and shelf life extension.

Food Waste Reduction

Reducing food waste is a critical aspect of sustainability, and our PrecisionVac technology directly contributes to this effort. By rapidly processing food and extending shelf life, our system helps minimize spoilage throughout the supply chain.

- Extended shelf life through rapid cooling and treatment.

- Improved food safety through faster processing.

- Better quality preservation leading to less waste.

PrecisionVac technology helps you turn potential waste into profitable product by keeping food fresher, longer.

Sustainable Manufacturing Practices

Our commitment to sustainability extends to the manufacturing footprint of our equipment. By offering higher throughput per unit compared to traditional systems, we reduce the number of machines required to achieve the same output, leading to substantial material and manufacturing savings.

Reduced Manufacturing Footprint:

Processing the same amount of food per day may require only 1 PV-Rack compared to 3 blast chillers, significantly reducing the CO2 emissions associated with manufacturing extra units.

Material Savings:

The need for fewer units translates directly into savings on the materials required for construction, contributing to lower embodied carbon emissions.

Efficient Design:

Modules can be separated for space optimization, potentially reducing the physical space required compared to equivalent traditional setups.